In today’s world, plastics are everywhere – from simple household items to advanced aerospace components. But not all plastics are created equal. While commodity plastics like polyethylene (PE) and polypropylene (PP) are used for disposable packaging and everyday goods, engineering plastics stand apart due to their superior mechanical, thermal, and chemical properties.

This blog explains what engineering plastics are, their types, advantages, applications, and future trends, helping industries and professionals understand why these materials are vital for modern manufacturing.

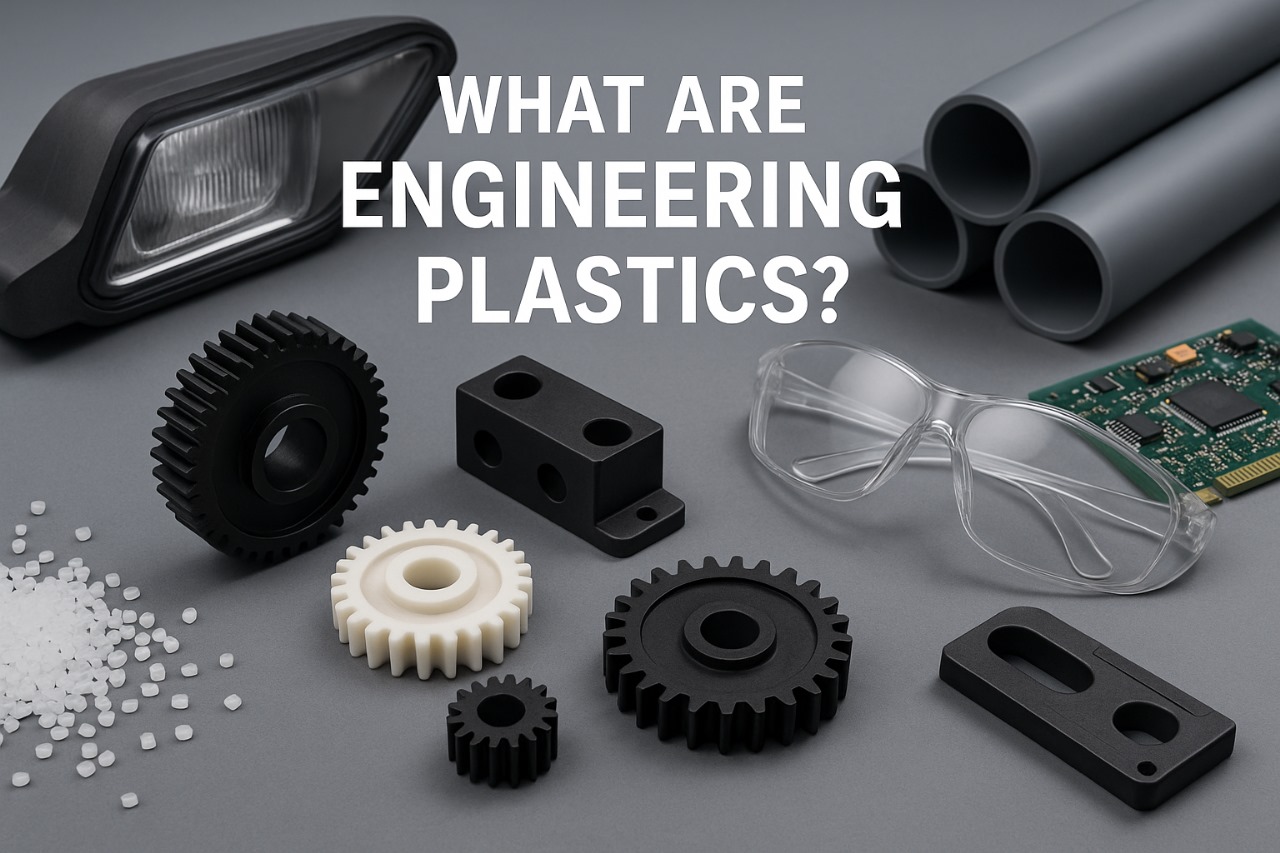

What Are Engineering Plastics?

Engineering plastics are a class of high-performance polymers designed to replace metals, glass, and ceramics in demanding applications. Unlike standard plastics, they can withstand high mechanical stress, elevated temperatures, and aggressive chemicals—all while being lighter and easier to process.

Key Features of Engineering Plastics:

• High strength and stiffness

• Good heat and impact resistance

• Dimensional stability

• Excellent electrical insulation

• Resistance to chemicals and wear

• Lightweight compared to metals

Types of Engineering Plastics

Polyamide (PA / Nylon)

Known for toughness, wear resistance, and self-lubricating properties.

Applications: gears, bearings, automotive components.

Polycarbonate (PC)

Transparent, impact-resistant, and lightweight.

Applications: safety helmets, optical lenses, automotive headlights.

Polyoxymethylene (POM / Acetal)

Excellent dimensional stability and low friction.

Applications: precision parts, gears, conveyor belts.

Polyethylene Terephthalate (PET) & Polybutylene Terephthalate (PBT)

High strength, chemical resistance, and electrical properties.

Applications: automotive connectors, electronics, food packaging.

Acrylonitrile Butadiene Styrene (ABS)

Good toughness and easy to process.

Applications: consumer electronics housings, automotive interiors, toys.

Polyphenylene Oxide (PPO) & Polyphenylene Sulfide (PPS)

Superior chemical resistance and high-temperature stability.

Applications: pump parts, electrical housings, automotive components.

Advantages of Engineering Plastics

• Weight reduction compared to metals, improving fuel efficiency in vehicles.

• Durability in harsh conditions (heat, moisture, abrasion).

• Design flexibility, enabling complex shapes through injection molding.

• Cost-effectiveness, as they require less maintenance and longer life cycles.

• Sustainability, with many grades available in recyclable or bio-based forms.

Applications of Engineering Plastics

1. Automotive Industry

• Engine components, dashboards, bumpers, under-the-hood parts.

2. Electrical & Electronics

• Switches, connectors, circuit breakers, LED housings.

3. Medical Devices

• Surgical instruments, prosthetics, diagnostic equipment.

4. Construction & Industrial Uses

• Pipes, fittings, chemical tanks, flooring systems.

5. Consumer Goods

• Sports equipment, furniture, household appliances.

Future of Engineering Plastics

With the global shift towards lightweighting, energy efficiency, and sustainability, the demand for engineering plastics will continue to rise. Emerging trends include:

• Reinforced composites with glass/carbon fibers.

• Biodegradable engineering plastics for eco-friendly solutions.

• Smart materials with improved fire resistance and conductivity.

Frequently Asked Questions (FAQs)

Q: What is the difference between commodity plastics and engineering plastics?

A: Commodity plastics are used for low-stress, disposable applications, while engineering plastics are designed for high-performance, durable applications.

Q: Are engineering plastics recyclable?

A: Yes, many engineering plastics like PET, PA, and PC have recyclable grades, though recycling can be more complex compared to standard plastics.

Q: Which industries benefit the most from engineering plastics?

A: Automotive, electronics, aerospace, construction, and medical industries are the biggest users.

Conclusion

Engineering plastics represent the backbone of modern engineering and design. Their ability to combine strength, durability, and versatility makes them an ideal substitute for metals and ceramics in countless industries. As technology advances, engineering plastics will continue to lead innovation in manufacturing, sustainability, and product performance.

![Logo_-_Polymer_XS_R[1]-02 Logo_-_Polymer_XS_R[1]-02](https://polymerxs.com/wp-content/uploads/2025/08/Logo_-_Polymer_XS_R1-02-1-scaled-e1758553349813.png)